Motorcycle Parts New Zealand Specialists Things To Know Before You Buy

Table of ContentsThe Ultimate Guide To Motorcycle Parts New Zealand SpecialistsGetting My Motorcycle Parts New Zealand Specialists To WorkMotorcycle Parts New Zealand Specialists Fundamentals ExplainedSome Known Details About Motorcycle Parts New Zealand Specialists Fascination About Motorcycle Parts New Zealand SpecialistsThe Greatest Guide To Motorcycle Parts New Zealand SpecialistsWhat Does Motorcycle Parts New Zealand Specialists Mean?Motorcycle Parts New Zealand Specialists - The Facts

So, get to out to among our specialists today.CNC machining innovation is rapidly ending up being the focal factor of various production procedures around the world as a straight outcome of its many benefits over other methods. Furthermore, the markets that make bikes have hopped on board with this fad. The most ingenious firms are currently creating their engine parts and wheels making use of machining strategies initially established for motorbike parts.

On the various other hand, the results of sector are the main emphasis of this short article. Allow's obtain straight into it. You might be wondering why we use. It is not tough to fathom the variables that caused this result. Now that we have your focus allow us clarify the rationale behind this modern-day advancement in the motorbike manufacturing sector.

A Biased View of Motorcycle Parts New Zealand Specialists

Furthermore, you have full control over the appearance of the elements, even to the min information. Occasionally, motorcyclists might determine to spruce up their trip by installing aftermarket parts or changing the bike's transformation. Once once again, computer system numerical control (CNC) machining is one of the most practical approach. Upgrades might be of any type of type and design you desire.

The 5-Minute Rule for Motorcycle Parts New Zealand Specialists

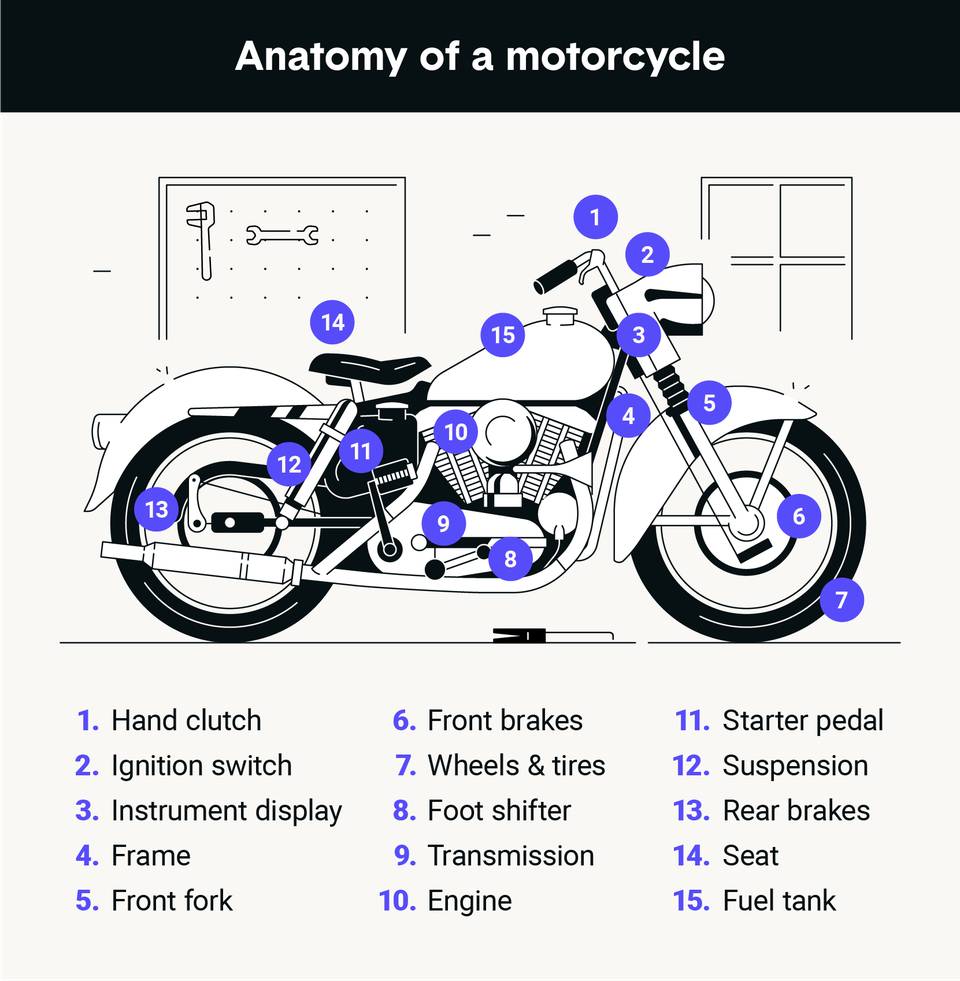

CNC machining might be made use of to make mostly all of a motorcycle's metal and plastic components. To proceed, we'll go over several machined parts for bikes. In comparison to those on cars, wheels on motorbikes often tend to be more evident. As a result, the bike's appearances might be boosted with the appropriate personalization of these wheels.

Milling treatments are used to get the desired degree of wheel personalization. Another facet of the motorbike that might be customized is the tires.

An Unbiased View of Motorcycle Parts New Zealand Specialists

When it involves a lorry (or a motorbike), the most vital element is the engine. A number of people allude to it as the "heart" of the vehicle. On the other hand, the camshaft, the cylinder head, and the pistons have a tendency to be intricate and call for layouts with a high level of accuracy.

Lighting is an additional complicated aspect of customization. Use just high-grade products, however, since these lights are critical for the security of motorcyclists and other chauffeurs or people on the road, especially at night. Motorcycle fronts lights have 3 main parts: the light bulb, or light source, the lens, and the housing. In particular, we tailor the lens and the housing.

Milling procedures with a perfect surface would certainly cause the lenses having a reflective high quality that is similar to that of a mirror. The cover, on the various other hand, is not composed of delicate materials; rather, it is created out of hard polymers that can be machined into more complex patterns.

Motorcycle Parts New Zealand Specialists Can Be Fun For Anyone

They usually have fancy geometries with a wealth of minute information. Motorbike makers commonly cast these parts, but just for the manufacturing of bespoke parts. However, CNC machining is the method of selection when generating unique pieces. Machining on five axes in today's world is the means whereby any type of layout form may be realized.

Pick Runsom for your my website tailored bike components! We have the ability to fabricate complicated and trendy components making your bike unparalleled.

Right here are a couple of examples of steels often used in motorbike component machining. Aluminum is the primary material made use of by companies specializing in creating custom-made motorbike elements to produce most of these parts - Motorcycle Parts New Zealand Specialists.

Zinc describes one more steel that is really light in weight and has wonderful machining top qualities because of its high mechanical stamina. This product may be developed into almost any kind of form and preserves its measurements well. Also mission-critical components that need a high level of precision may profit from their usage.

Some Known Factual Statements About Motorcycle Parts New Zealand Specialists

One more steel that sees hefty use in the manufacturing of CNC-customized components is magnesium. It is amongst the lightest steels that are now easily accessible and has superb machinability attributes and strength appropriate with its reduced weight. Among the disadvantages of magnesium is that its dust might quickly capture fire.

As a result of its premium machinability and weldability, stainless-steel is an alloy that is specifically fit for CNC procedures. In enhancement to this, they have great deterioration resistance and a high visual allure. Their most typical usage in producing various motorcycle parts is fasteners, such as screws and bolts. Their reduced susceptibility to oxidation and deterioration makes them optimal for this use.

What Does Motorcycle Parts New Zealand Specialists Mean?

It seems that CNC transforming and milling are the fundamental processes. In addition, it calls for maintaining bars of product, most usually plastic or metal, in position and after that turning a reducing tool to eliminate sections of the material as the material is turned.

These methods are equally important and create elements with high precision and consistent top quality. The procedures assist enhance the general quality of the machined motorbike elements.

Getting The Motorcycle Parts New Zealand Specialists To Work